Yes, the Ressence Watch certainly stands out from most other watches. The obvious simplicity, rounded shapes and thoughtful use of colour make Benoît Mintiens’ work very clear. Branded oil-filled watches (types 3, 5, recently introduced 7) should tell the founder’s functional philosophy of Best Express: Mechanical Watch in the most user-friendly way. It sounds very logical, but behind all its simplicity is the world of research, development and experimentation. We visited Benoît, at the headquarters of Ressence in Antwerp, Belgium, to learn more.

The biggest challenge is that every glow clock has mechanical movement in the heart. This is one of Benoît’s non-negotiable requirements. According to him, the watch requires internal mechanical movements to allow people to emotionally connect with it. Furthermore, the watch serves the wearer, so readability and ergonomics are of paramount importance to him. Therefore, it is easy to read at a glance and should not be in the way when doing so. Benoîts already had the idea of an oil-filled dial with screen-like sharpness and minimal amount of reflection from the brand in early 2010. However, it took quite a while to achieve the seemingly simple execution brilliance that we reached with the new Type 7. Today we’ll see the journey.

Magnetic transmission

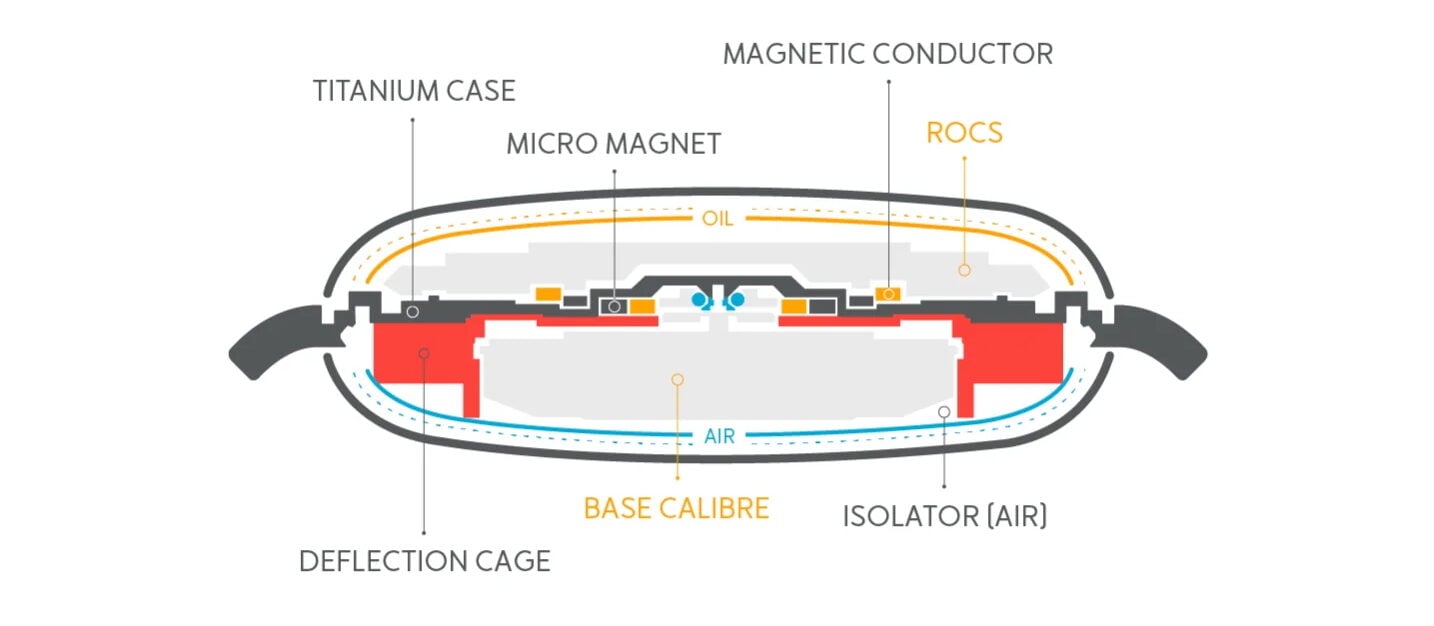

In Type 3, Benoît’s first idea was to sink both the mechanical movement and the Ressence Orbital Convex System (ROCS), which are responsible for the movement of the satellite around the dial. In that case, the user will need to set the movement from the outside of the watch using some kind of magnetic tool. However, if mechanical movements are soaked in oil, the escape no longer works properly. That’s when the idea of two separate enclosed chambers was born. One is the dry, moving side, and the other is the wet dial side.

Instead of the axis connecting the two parts, Benoît developed magnetic permeation. This means there are multiple micromagnets (1mm) × 0.5mm each) In each chamber that connects them. But anyone who knows a bit about mechanical movement also knows that magnetism can be harmful to the accuracy of a watch. To prevent this, the all-oil-filled Ressence watch has a deflection cage around mechanical movement. It is also the reason why Resance uses titanium for its case structure, as it is a non-magnetic metal. This means that it does not attract or repel the magnet. Although not the case with aluminum, it is less elastic than titanium, making it difficult to work with.

Early Type 2 Prototype with older versions of the Crown

Types 5 and 3 each have updated crowns

New Type 7 with updated crown system

Gravity setting and crystal fixation

In the first model of RESSENCE Type 3, the crown function (the entire case) depends on how it held the watch. If you were looking at the dial, that meant the crown would set the time. If you turned the watch upside down, it meant you could wind it. This gravity system caused some problems, and Lessence later replaced it with a more user-friendly crown. This system is still in place today.

Another feature of Ressence Watches is its pebble-shaped crystals. However, this results in some complications. Benoît required many attempts to secure the crystal into the case. On regular watches, the bezel holds the crystal in place. However, the Ressence watch does not have a bezel. Finally, the crystal is glued to the case and baked in the oven for even more secure fixation. Other brands like Swatch use this method too.

For Type 5, the watch had to withstand two impact forces equivalent to 5,000 g, so the response had to use thicker crystals. This was necessary to pass the hammer test for ISO dive watch certification.

Different types of oil

When Benoît began experimenting with the concept of oil-filled clocks, he used oil for the Navy compass. He only needed about 3.57ml per watch, so he sourced a small amount from the guy who fixed those compasses. However, when he wanted to buy it directly from a third party, he had to buy the entire barrel. It was a bit so he switched to the oil used to make candles. But the problem was that this type of oil had a yellow effect on the Super Luminova used in the dial. In the end, he found a silicon-based UV-resistant oil and caused no problems.

Type 5 ready for assembly including 7 rubber bellows and its cage

Films were initially embedded in the case of titanium to compensate for changes in oil volume due to temperature fluctuations within the clock. This membrane was later replaced by a bellows system. Initially, the bellows were made from gold-plated nickel. However, they wear very quickly, so the glow has been switched to the rubber ones that are used recently.

Filled at -5°C

In addition to this bellows system, if you prevent air bubbles from forming inside the watch, the oil will enter the watch at -5°C. The clock is then spent overnight in the freezer. This is to ensure that the internal pressure is always higher than the outside.

Each oil-filled watch allows you to monitor the oil temperature of a specially developed subdial. Types 3 and 5 have a hand indicating the temperature, and in the new Type 7 it is simply a window that displays the corresponding colors. Blue represents cold, while green means it’s just right, yellow and red indicate that the oil is too warm.

In theory, oil temperature can vary between -5 to 55 degrees within the watch. But just as Benoît showed me with the watch he was wearing, the temperature on the wearer’s wrist also affects it. This means that in average climates the temperature inside the clock is always around 26°C.

Oil bath service

Antwerp’s Ressence Office has one room dedicated to branded watchmakers. There, oil-filled watches are served. If service is required for an oil-filled ROCS module, this occurs in the oil bath. However, this is rare as there is little wear or tear inside the oil-filled chamber. However, if the crystal breaks for example, then of course you need service.

Innovation never stops

As you can see, since the introduction of Type 3 in 2013, Ressence oil-filled watches have always been the subject of innovation. Compared to Types 3 and 5, Type 7 ROCS modules come with gem bearings instead of regular shafts, gems and gears. This is a concept taken from Type 2, allowing for a much slimmer construction. The only downside is that you can hear these ball bearings rattle when you shake the watch. This doesn’t mean the clock isn’t well built, but the sound looks like that. This is what Benoît is trying to solve for future treats watches.

For me, the oil-filled glow clocks and the necessary research, development and experiments behind them show exactly that the dedicated Benoît Mintiens is to achieve his goal of creating the most user-friendly mechanical watches. On top of that, he makes them look clean, colorful and more than anything unique. I’m very excited to see what Benoît has on his sleeves and how he perfects his already very easy to use and good looking lineup.

In the comments below, let us know what you think of Ressence’s oil-filled watches.

This is a post for a priority position. learn more.