Russell Sheldrake

In our industry, the terms in-house and manufacturing are thrown around a lot. These are the buzzwords that can kill a brand, and we’ve seen brands come under heavy criticism for misleading usage. So whenever we are given the chance to venture into a brand’s manufacturing center, we find it very interesting to see exactly what it is. How “in-house” they are in their own homes. I’ve been doing this job for 10 years, and I’ve been fortunate enough to visit many manufacturers. There are usually sections or rooms where taking photos or videos is prohibited, but this was the place. It was the first time I had to lock my phone before a tour started. So, with my precious communication device kept in a Germanic prison, I set out to explore the campus that A. Lange & Söhne calls home.

First, let me explain where exactly we are. Unlike most industries, we are not located in Switzerland, but in Germany, close to the eastern border with the Czech Republic. So close, in fact, that we flew into Prague and drove the short distance to Glashütte, the watchmaking town that around 7,000 people call home. A. It was my first time visiting Lange & Söhne, and even before I entered the building, the first thing that struck me was the sheer size of the building. The buildings are lined up around a small plaza, giving it the feel of a high-end university campus. With over 700 employees working at the company and many different facets and skills being developed here, it’s clear how the brand needs so much space.

Each building has a different purpose, including a school to train the next generation of watchmakers, but our main focus was on a five-story, large-windowed production facility that officially opened in 2015. is another movement building division with increasing levels of complexity as you move up the building. But before we get into the movements, we had to check out the sculpture department first, because there is one decorative art that A. Lange & Söhne is especially famous for.

hand carving

A visual element that has distinguished every Lange movement since the brand’s relaunch in 1994 is the hand-carved balance cock. So it’s only natural to pop your head around these uniquely carved doors. Industry legend says that each craftsman’s skills are so unique that you can tell exactly who worked on which watch just by examining the balance cock. Luckily, my good friend Justin Hast from Time+Tide was also on the tour and had his Lange 1 with him so I was able to test it out. So I threw it under the microscope and out came this folder with a unique pattern associated with every engraver who ever worked for A. Lange & Söhne. After looking through it for a while, I discovered that Justin’s watch was created by Helmut Wagner, one of the brand’s most prolific engravers and at one time head of the department.

Alongside those busy carving around 10 balance cocks a day, others were also working on other hand-carved components, which mainly appear in the Handwerkskunst edition. It was interesting to watch these artisans work with heads glued to microscopes, among the hand-hammered dials and customizations throughout the room. When speaking with these master craftsmen, it was clear how passionate they are about what they do, seeing how highly they speak about other watchmakers and brands that do the same work. . Certainly, there is no sense of “us versus them” here.

Creating movement from the top down

Now onto the real meat and potatoes (or should it be bratwurst and sauerkraut?) of this visit. It is the aforementioned movement manufacturing building that opened in 2015. It’s laid out in a very hierarchical format. The simplest or basic movements are generated at the lower levels and become progressively more complex as you move up to the upper levels. This means that the most skilled watchmakers are housed in penthouses overlooking the picturesque city.

We started where all budding watchmakers at A. Lange & Söhne start: in the Lange 1 division. The first thing that struck me when I entered was how young everyone looked. There aren’t many things in the watch industry that, at 29 years old, make me feel old, but the young watchmakers here looked like half of them hadn’t yet ordered their first legal beer. We are confident that everyone there is trained in all aspects of horology, and seeing them at work will fully believe it. I was given a breakdown of the Lange 1 movements, one of which was completely disassembled for viewing. This allowed us to see all 380 oil points and understand why it takes 6-10 months to manufacture one of these calibers. Not only did we see the beginning of a watchmaker’s journey with this company, but the movement of the Lange 1, caliber 121.1, is also the basis for many other movements created by this German company, and we You’ll see that as we move forward. Go up the building.

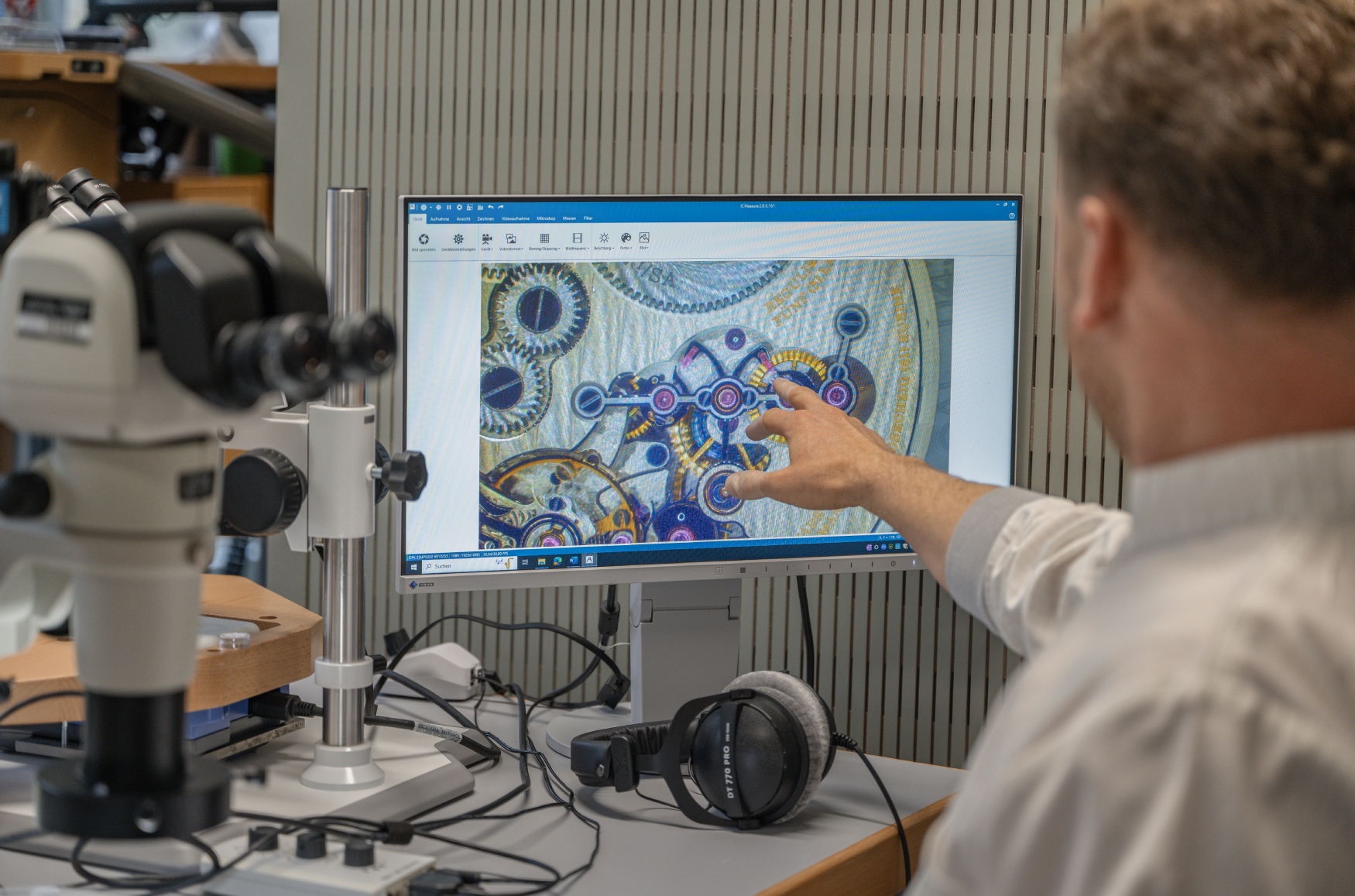

Next we were shown to our Zeitwerk room. Once again, there were long benches facing the floor-to-ceiling windows, on which the slightly older watchmakers were bent. This time, we were given a close-up look under a microscope at the complex adjustment system that works inside L043.6. While this feature is mesmerizing and beautiful to look at, it is also highly functional, allowing for the large power output needed to keep the hours and minutes jumping on these digital display watches that have become iconic of the brand. .

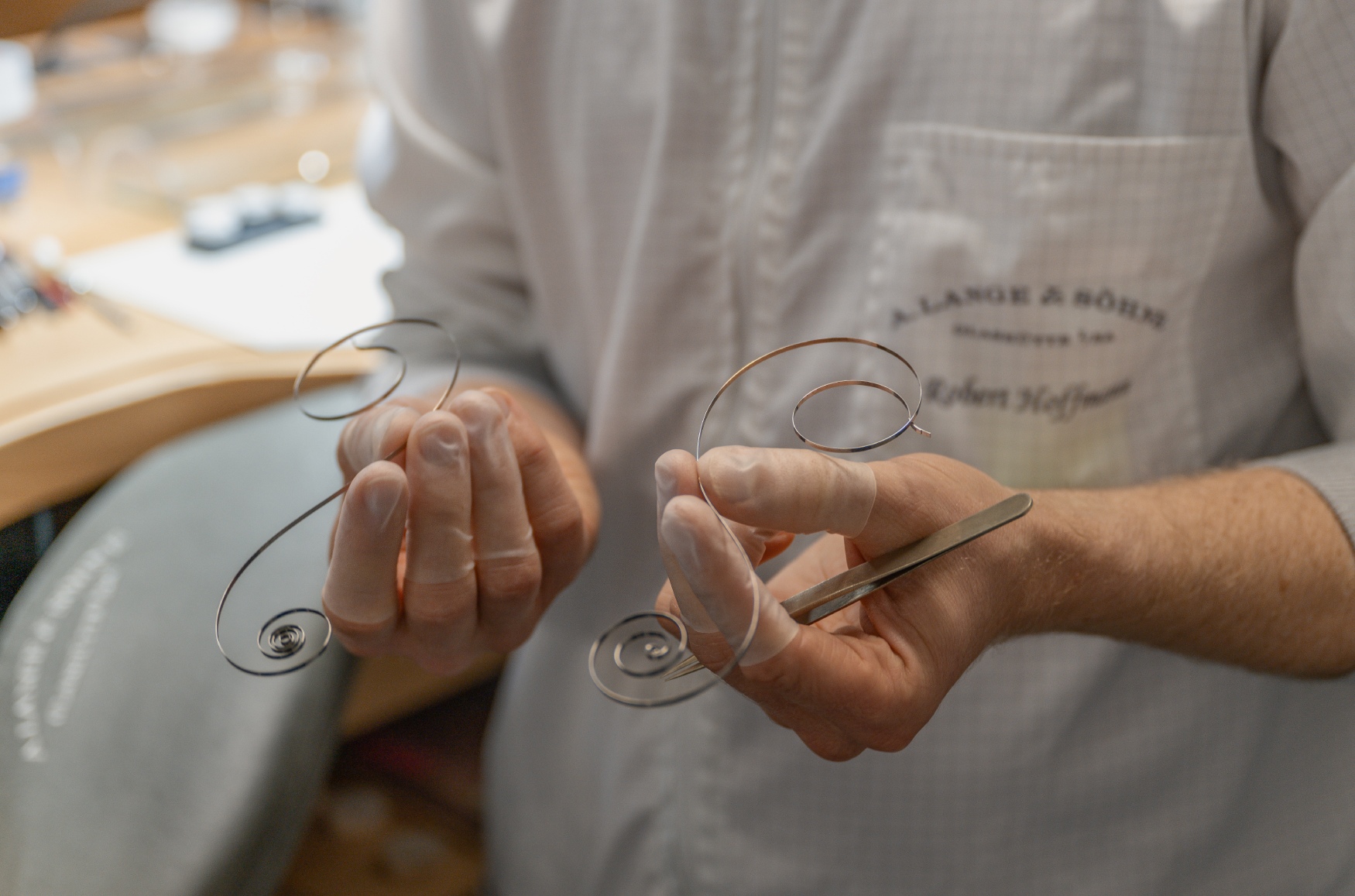

While it’s fun to watch these tiny regulators whirl around, it’s much more tangible to see the two giant mainsprings used to provide this movement with a 72-hour power reserve. When these pieces of metal are unwound and exposed outside the barrel, they look more like ribbons than something that can be tightly wrapped inside a movement component. You rarely get to see these types of components this way. That way you can better understand how complex and intricate these micro-mechanisms really are (at least they were for me). I have a whole new respect for the people I get to understand and work with on a daily basis.

After gaining this new perspective in the Zeitwerk room, we ascend to the top floor of the building on another floor, where Lange’s most complex movements are compiled. This last floor had the best views and the most natural light, but it was also the most calming floor. Everyone there worked in near silence, and you could feel the talent of the watchmakers as you entered the room, giving the atmosphere a pleasant cross between an exam hall and a luxury spa. The sense of relaxed focus and confidence was palpable as I witnessed the wonderfully complex movement at work in the 1815 Rattrapante Perpetual Calendar.

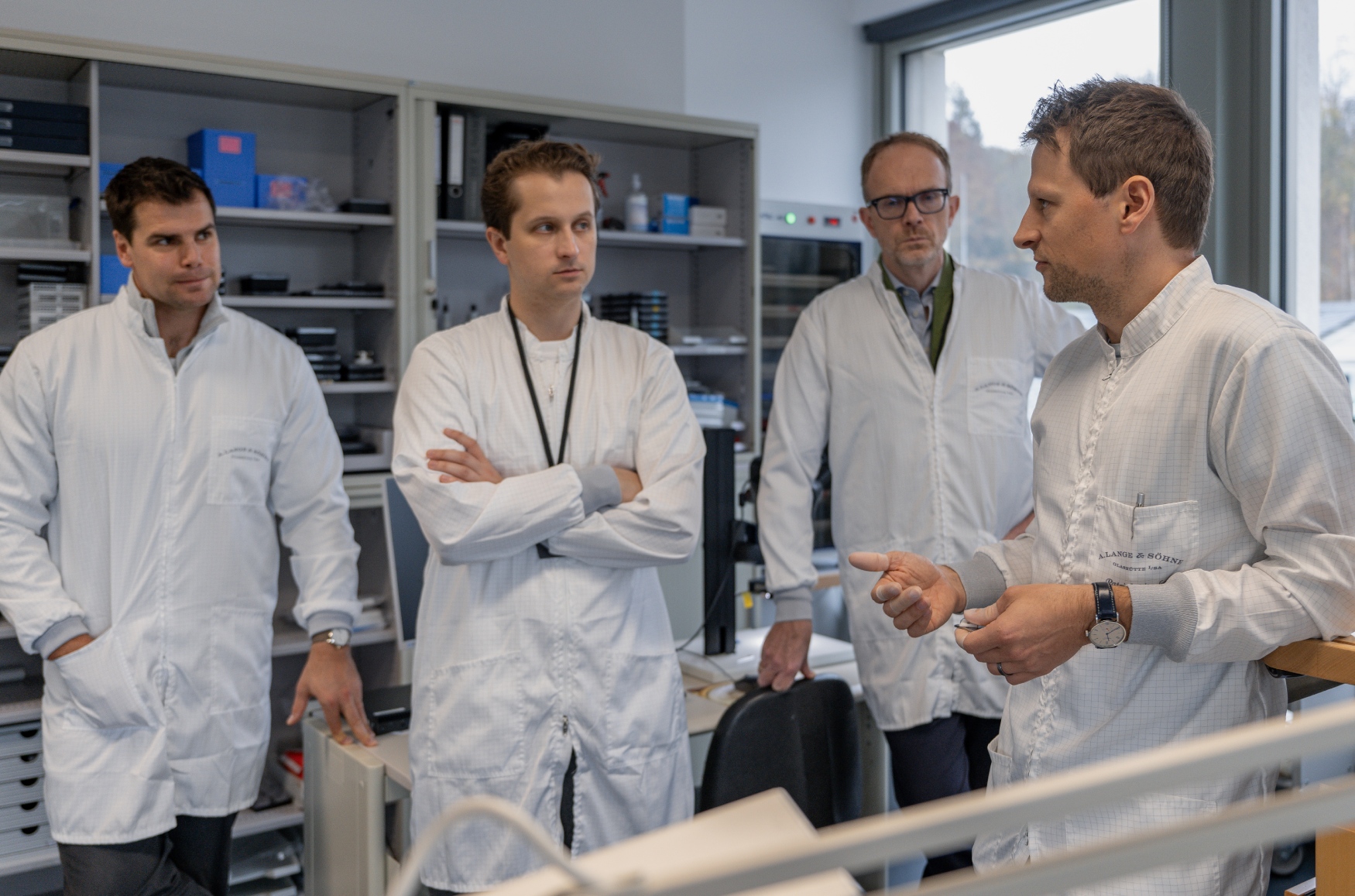

As we talked about things both inside and outside of the departments that can build these highly complex movements, the topic of where watchmakers are going from here came up. Now that they’ve reached the top of the mountain, so to speak, the question arises: what’s next? Once a watchmaker has worked at Lange for a certain period of time, they are given the time to design and build their own watch from scratch using Lange parts and tools. This tests theories and ideas that can be developed into new brands, as two former Lange watchmakers, Johannes Kalinic and Thibault Clais, did when they founded Einser Zentralsekunde. That’s a great method.

Finished product

After touring the High Complications Department, it’s time to return to Earth and discover the entire A. Lange & Söhne collection, housed in the house where Ferdinand Adolf Lange first ran the company. Fortunately, the building is just a short walk from the campus-style manufacturing facility where we currently produce our modern collection.

Speaking of this modern collection, as we entered what used to be F.A. Lange’s dining room, we saw (almost) the entire Lange catalog laid out for us to view and photograph. . As anyone who has visited a Lange boutique will tell you, this is something very rare. Given the small number of each watch produced and the historically high demand, it’s rare to find them all under one roof.

This was a great way to end our tour. We could see all the components in the works coming together in their final form, along with a long line of Germanic-style watches with oversized date windows and asymmetry. Dial layout everywhere you look.

What struck me when looking at this lineup was what could be in store for A. Lange & Söhne in the coming months and years. It’s clear that the watch industry is going through tough times right now, but Lange has always felt like a constant for me. No matter what, the brand releases a small number of novelties each year that remain true to the guidelines set by Günter Blümlein in 1994 and realized in 1999. Some of these are small advances that show how Wilhelm Schmidt, Anthony de Haas, and their team have been working. Pay as much attention to the small details as the big picture. But how long can the company continue to operate this way if the market continues on its current trajectory? So far, it has managed to weather the financial uncertainties the 21st century has thrown at us all. However, it remains to be seen whether A. Lange & Söhne will maintain this policy or change its strategy towards the end of the second half of the year. In the 2020s.